陈鹏基,甡物科技联合创始人兼首席技术官,国家认证中级材料工程师,携十余年可持续产品开发经验,致力于推动材料领域的全面创新。他带领团队研发了“茶原聚合技术”,该技术可将农作废弃物转化为高价值的绿色新材料,并推出了 “植物纤维复合材料” 解决方案,已荣获包括中国、美国在内的十余项发明专利及外观设计专。在此基础上,陈鹏基还推动了新材料生产线的智能化与自动化升级。在提高生物基材料的生产效率、降低成本和减少碳排放方面,陈鹏基的贡献尤为显著。

自2022年携手创立甡物科技以来,陈鹏基与团队共同见证了公司的飞速发展:从2023年成功获得阿里巴巴创业者基金和戈壁大湾区数百万美元的种子轮融资,到2024年获得香港科技园战略合作,将会获得数百万港币支持。从项目研发到获得两轮战略合作资金,陈鹏基积累了丰富的实践项目经验和感悟,对新材料行业战略布局和战略举措逐渐形成了深刻的理解。

在全球资源利用和环境污染问题日益严峻的当下,联合国环境规划署发布的《2024年全球资源展望》报告指出,世界正处于气候变化、生物多样性丧失、污染和废弃物的三重地球性危机之中。其中固体废物的产生量预计将从2023年的23亿吨增长到2050年的38亿吨。如果不采取紧急行动进行废物管理,到2050年,全球每年的废物管理成本可能几乎翻倍,达到6403亿美元。在此紧迫形势下,陈鹏基团队的研究与努力显得尤为关键。他们的工作不仅聚焦于废弃物处理,更深入探索了如何高效转化和循环利用这些资源,以助力地球实现可持续发展的长远目标。

茶原聚合技术引领:循序渐进,助推产业绿色转型

作为世界上最大的茶叶生产国,我国茶叶年产量高达近三百万吨,每年产生的茶渣数量亦高达数十万吨。同时,我国每年约有1.2亿吨竹子成熟,却未能得到充分利用。除此之外,还有众多富含东方特色的材料未能发挥其最大价值。这背后反映出东方特色材料资源的巨大潜力与当前利用不足之间的矛盾,亟待我们探索更有效的途径来减少资源浪费,实现可持续发展。

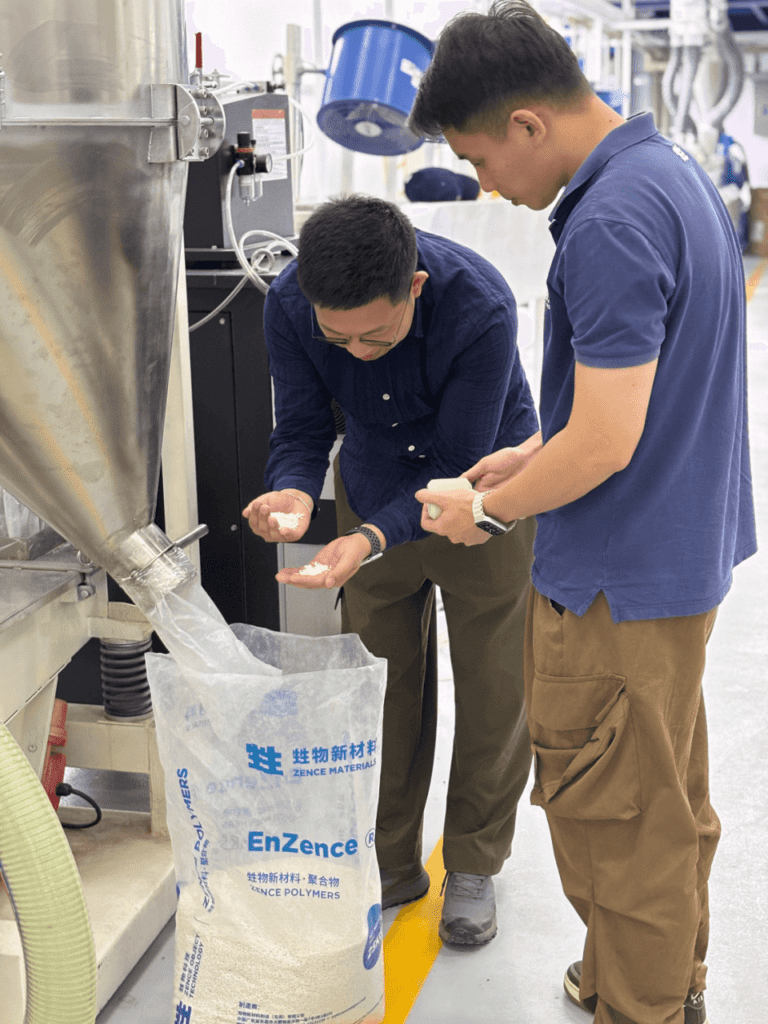

陈鹏基团队以此为使命,以茶为源,自主研发了“茶原聚合技术”,将茶转化成具有高价值的 “茶塑”。该团队的探索始于茶,却不止于茶,他们已经成功从茶叶和竹子中提取出的植物纤维和木质素等有价值的元素,推出了一系列独具植物纤维质感的创新产品。基于 “茶原聚合技术” 这一核心技术,团队进一步拓展至再生材料技术领域,专注于挖掘和有效利用具有东方属性的材料,如甘蔗渣、中药渣、桔梗、荷叶等材料,致力于展现其独有的东方魅力。

陈鹏基团队秉持“物尽其用”的环保理念,将原本废弃的茶叶和竹子巧妙转化为高价值材料,不仅有效解决了废弃物处理问题,还将蕴含东方特色的材料推广到了更广阔的市场。这些材料拥有优异的机械性能,能够广泛应用于电子产品外壳、日化产品包装、汽车内饰、建筑材料等多个行业。陈鹏基团队的创新材料已助力多家行业头部企业实现绿色转型,为新材料产业链的可持续发展开辟了新的道。

引领新材料生产线向智能化与自动化迈进,显著提高生物基材料的生产效能

在自动化生产线方面,陈鹏基携手技术团队共同创新,成功研发多项设备发明专利,显著提高了植物纤维材料和生物基材料的生产效率,推动了产业技术进步。

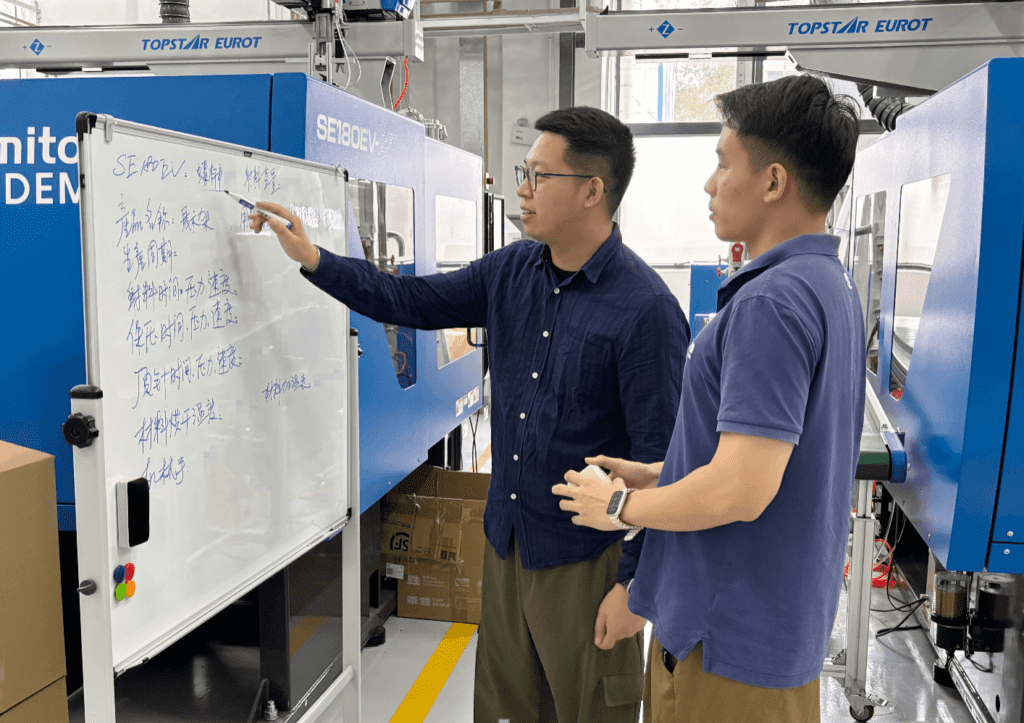

在生物基材料成型方面,在陈鹏基的主导下,日本住友重械设立了国内首个生物基材料成型研发中心,共同致力于绿色可持续发展的道路。使得生物基材料的成型效率得到了极大提升,同时也保证了产品的高质量成型,成功破局生物基材料面临的低效生产、高难成型标准、低成型率及量产瓶颈,引领了生物基材料量产的新革新。

目前,甡物科技的智慧工厂 能耗和更少碳排放。预计该工厂的年产值将突破亿元。

可持续路径:从源头到回收实现闭环

针对全球废弃物挑战,陈鹏基提出了“源头减量、循环利用、推动回收”的三位一体策略,旨在助力全球减塑目标的实现。陈鹏基及其团队已运用东方智慧,通过自主研发的专利技术和先进设备,从源头上实现减塑降碳。

展望未来,他们正筹划携手更多合作伙伴,将新材料的价值链转化为循环经济链。通过与产业链上下游企业及各地回收企业的深度合作,打造更低能耗、更高效率的“Zence™”回收体系,提升新材料回收利用率,推动产业绿色循环可持续发展。最终,由甡物科技生产的材料,在完成其生命周期后,能够被有效回收并重新投入生产流程,经过专业的分离和提纯处理,再次成为新的产品,形成闭环,共同创造一个更加绿色的未来。

“我们坚信,每一个创新都应以促进人与自然和谐共生为目标。我们团队已成功研发并推广了茶原聚合技术与植物纤维复合材料解决方案。我们不仅致力于寻找传统材料的有效替代品,更积极探索实现资源高效利用与循环经济的道路。我们致力于构建一个从源头到回收的完整闭环可持续体系,确保每一份材料都能在生命周期结束后,再次焕发新生。这不仅是对当前环境挑战的积极回应,也是贯彻国家双碳目标和新质生产力理念的具体行动。希望通过我们的不懈努力,能够为地球带来真正的改变。促使 “生生不息,永续未来” 的理念跨越团队的界限,成为人人参与、人人共享的美好现实。” 陈鹏基说。

英文版:

Jay Chen, co-founder and Chief Technology Officer of Zence Object Technology, a nationally certified intermediate materials engineer, brings over ten years of experience in sustainable product development and is committed to promoting comprehensive innovation in the field of materials. He led the team to develop the”EnZence©(Tea Polymerization Technology)”, which can transform agricultural waste into high-value green new materials, and launched the “Plant Fiber Composite Material” solution, which has won more than ten invention patents and design patents in countries including China and the United States. On this basis, Jay Chen also promoted the intelligent and automated upgrading of the new material production line. Jay Chen has made particularly significant contributions in improving the production efficiency of bio-based materials, reducing costs, and reducing carbon emissions.

Since co-founding Zence Object Technology in 2022, Jay Chen and the team have witnessed the company’s rapid development together: from successfully obtaining millions of dollars in seed round financing from the Alibaba Entrepreneurs Fund and Gobi Greater Bay Area in 2023 to securing a strategic cooperation with the Hong Kong Science and Technology Park in 2024, which will bring in support of several million Hong Kong dollars. From project research and development to obtaining two rounds of strategic cooperation funds, Jay Chen has accumulated rich practical project experience and insights, and has gradually formed a profound understanding of the strategic layout and initiatives in the new materials industry.

In the current context where global resource utilization and environmental pollution problems are becoming increasingly severe, the “Global Resources Outlook 2024” report released by the United Nations Environment Programme points out that the world is in the midst of a triple planetary crisis of climate change, biodiversity loss, pollution, and waste. The amount of solid waste is expected to increase from 2.3 billion tons in 2023 to 3.8 billion tons in 2050. If no urgent action is taken for waste management, by 2050, the annual global waste management cost could almost double to $640.3 billion. Under this urgent situation, the research and efforts of Jay Chen’s team are particularly crucial. Their work not only focuses on waste disposal but also delves deeper into how to efficiently transform and recycle these resources to help the earth achieve the long-term goal of sustainable development.

Led by the Tea Polymerization Technology: Step by Step, Boosting the Green Transformation of the Industry

As the world’s largest tea producer, China’s annual tea production is as high as nearly 3 million tons, and the amount of tea residue generated each year is also as high as hundreds of thousands of tons. Meanwhile, about 120 million tons of bamboo mature in China every year, yet they are not fully utilized. Besides, there are many materials rich in oriental characteristics that have not been able to maximize their value. This reflects the contradiction between the huge potential of oriental characteristic material resources and the current insufficient utilization, and it urgently requires us to explore more effective ways to reduce resource waste and achieve sustainable development.

Taking this as their mission and using tea as the source, Jay Chen’s team independently developed the “Tea Polymerization Technology” to transform tea into high-value “tea plastics”. The team’s exploration started with tea but did not stop there. They have successfully extracted valuable elements such as plant fibers and lignin from tea and bamboo and launched a series of innovative products with a unique plant fiber texture. Based on the core technology of the “Tea Polymerization Technology”, the team has further expanded into the field of recycled material technology, focusing on mining and effectively utilizing materials with oriental attributes, such as bagasse, Chinese medicine residues, platycodon roots, lotus leaves, etc., and is committed to showcasing their unique oriental charm.

Adhering to the environmental protection concept of “making the best use of everything”, Jay Chen’s team has ingeniously transformed the originally discarded tea and bamboo into high-value materials. This not only effectively solves the waste disposal problem but also promotes materials with oriental characteristics to a broader market. These materials have excellent mechanical properties and can be widely used in multiple industries such as electronic product casings, packaging of daily chemical products, automotive interiors, and building materials. The innovative materials of Jay Chen’s team have helped many leading enterprises in the industry achieve green transformation and opened up new paths for the sustainable development of the new materials industry chain.

Leading the New Material Production Line towards Intelligence and Automation, Significantly Improving the Production Efficiency of Bio-based Materials

In terms of the automated production line, Jay Chen, together with the technical team, jointly innovated and successfully developed multiple equipment invention patents, significantly improving the production efficiency of plant fiber materials and bio-based materials and promoting industrial technological progress.

In the aspect of bio-based material molding, under the leadership of Jay Chen, Sumitomo Heavy Industries of Japan established the first bio-based material molding research and development center in China, jointly committed to the path of green and sustainable development. This has greatly improved the molding efficiency of bio-based materials while ensuring the high-quality molding of products, successfully breaking through the bottlenecks faced by bio-based materials such as inefficient production, high molding difficulty standards, low molding rates, and mass production bottlenecks, and leading a new innovation in the mass production of bio-based materials.

Currently, the smart factory of Zence Object Technology consumes less energy and emits fewer carbon emissions. It is expected that the annual output value of the factory will exceed 100 million yuan.

Sustainable Path: Achieving a Closed Loop from Source to Recycling

In response to the global waste challenge, Jay Chen proposed a trinity strategy of “source reduction, recycling, and promoting recovery”, aiming to contribute to the achievement of the global plastic reduction goals. Jay Chen and his team have already utilized oriental wisdom to achieve plastic reduction and carbon reduction at the source through independently developed patented technologies and advanced equipment.

Looking ahead, they are planning to join hands with more partners to transform the value chain of new materials into a circular economy chain. Through in-depth cooperation with upstream and downstream enterprises in the industrial chain and recycling enterprises across different regions, they will build a Zence™ recycling system with lower energy consumption and higher efficiency, improve the recycling utilization rate of new materials, and promote the green, circular, and sustainable development of the industry. Eventually, the materials produced by Zence Object Technology can be effectively recycled and reintroduced into the production process after completing their life cycle. After professional separation and purification treatment, they will become new products again, forming a closed loop and jointly creating a greener future.

“We firmly believe that every innovation should aim to promote the harmonious coexistence of humans and nature. Our team has successfully developed and promoted the “EnZence©( Tea Polymerization Technology)” and the Plant Fiber Composite Material solution. We are not only committed to finding effective substitutes for traditional materials but also actively exploring ways to achieve efficient resource utilization and a circular economy. We are dedicated to building a complete closed-loop sustainable system from source to recycling, ensuring that every material can be rejuvenated after its life cycle ends. This is not only a positive response to the current environmental challenges but also a concrete action to implement the national dual-carbon goals and the concept of new quality productivity. We hope that through our unremitting efforts, we can bring real changes to the earth and promote the concept of ‘endless life and sustainable future’ across the world.” says Jay Chen.